A sound foundation

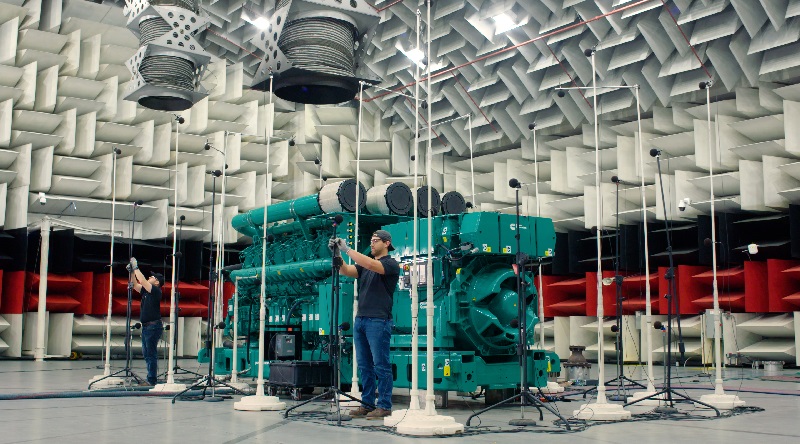

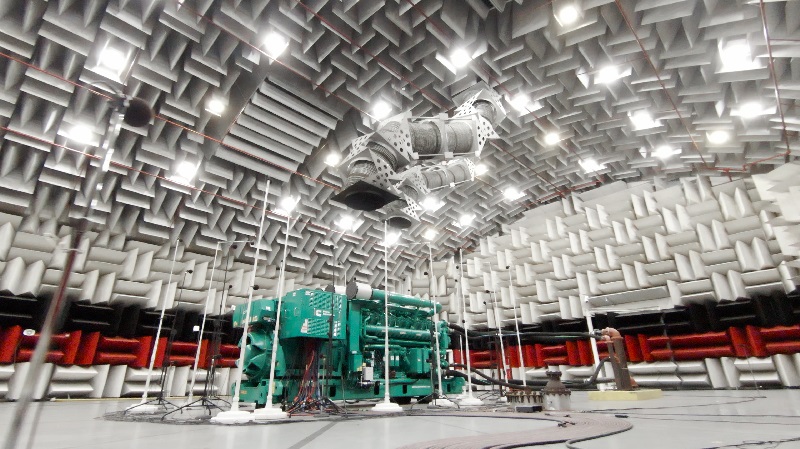

Cummins Acoustical Technology Center (ATC) located at the Cummins Power System factory in Fridley, Minnesota has a hemi-anechoic sound testing chamber with the ability to test and record precision-grade acoustical data from 20 Hz to 20,000 Hz… the entire range of the human auditory recognition.

Measuring at 105 feet long, 80 feet wide, and 36.5 feet high, the ATC is one of the largest of its kind in the world in diesel or power generation business and exemplifies Cummins’ commitment to innovation, precise engineering, and its dedication to providing quiet products for a sustainable future.

In tune with sustainability

The team’s commitment to innovation and precise engineering is reflected in the construction of the ATC. Despite its massive size, more than three-quarters of the materials used to build the center have been recycled or salvaged.

The building materials include recycled or partially recycled metal paneling, fly ash concrete and locally sourced material such as steel made from ore mined in northern Minnesota. In addition, the center was built on a site that qualifies as a brownfield redevelopment by the U.S. Green Building Council.

Extensive testing

10,000 hours of verification testing was conducted in the ATC to develop Cummins QuietConnect series of home standby generators—producing approximately the same level of sound as a human conversation.

Enclosing sound

Testing at the ATC helped in the design of the Cummins PowerBox genset enclosure. Precision acoustical data shows that the enclosure blocks the sound of the high horsepower diesel QSK78 genset until it is equivalent to the sound of rainfall.

Reduced footprint

Through extensive testing at the ATC, Cummins developed the next generation of potable generators: the Onan QG 2800i, which is 62.7% quieter than the previous product line with nearly a 50% improvement on fuel consumption.

Innovation at its best

0 K Hz The ATC can test and record precision-grade acoustical data from 20 Hz to 20,000 Hz—the entire range of human auditory recognition.

0 The design of the facility includes more than 2000 anechoic wedges that line the interior of the chamber.

0 °C A sophisticated air handling system moves 11 mm Btu/hr of waste heat to maintain 50% humidity and 23°C temperature at all times.

0 Measuring at 105 feet long, 80 feet wide, and 36.5 feet high, the ATC is large enough to house up to 20 school buses.